Archive for January, 2019

Home-Grown Zero-Carbon Hydrogen Technology

CSIRO’s Toyota Mirai HFC vehicle (image from CSIRO)

There are three possibilities when it comes to finding an alternative to the standard fossil fuels used in the majority of vehicles on the road. The first is a switch to biofuels (biodiesel, ethanol, etc.), the second is to go electric (the sexy new technology that’s mushrooming) and the third is hydrogen fuel cells or HFCs.

I discussed the basics of HFCs in my previous post. If you can’t remember or if you can’t be bothered hopping over to have a look, one of the points I raised was that most of the hydrogen gas used to power HFCs comes from natural gas, with methane (from sewage and effluent) coming in as the more sustainable second possibility. However, there’s another possible source of the hydrogen fuel that’s being worked on by our very own CSIRO researchers right here in Australia: ammonia.

Most of us are familiar with ammonia as the thing that makes floor cleaners (a) really cut through grease and (b) smell horrible. However, ammonia is also produced as a waste product by living cells and in humans, it quickly turns into urea and is excreted as urine. In fact, some of the pong associated with old-school long-drop dunnies comes from the urea in urine breaking back down into ammonia again (the rest of the smell comes from methane and some sulphur-based compounds, depending on what you’ve been eating).

Ammonia is chemically rendered as NH3, which should tell you straight away that there are three nice little hydrogen atoms just waiting to be turned into hydrogen gas; the leftover nitrogen is also a gas –and that’s one of the most common elements in the atmosphere (it makes up three-quarters of the earth’s atmosphere, in fact). Yes, ammonia in its pure form is a gas (the liquid stuff in household products is in the form of ammonium hydroxide or ammonia mixed with water). The fun here from the perspective of HFC technology consists of splitting the ammonia gas up into nitrogen gas and hydrogen gas, and then separating the two.

And this is precisely what the ammonia-to-hydrogen team at CSIRO have been working on. In August year, they made the big breakthrough by developing a membrane-based technology that will convert ammonia into hydrogen gas. The hydrogen gas can then be used by vehicles powered by HFC technology. The bit they’re all rubbing their hands with glee about is because up until now, one of the obstacles with getting HFC-powered motoring off the ground is that it’s hard to transport hydrogen gas from wherever it’s produced to the hydrogen equivalent of a bowser. However, ammonia is a lot easier to get from A to B. This means that with this home-grown technology, Australia will be able to export hydrogen (in the form of ammonia during transport) to the markets that want it.

Asia seems to be the hot spot for vehicles using HFC technology, with Toyota and Hyundai really getting behind the tech; European marques, on the other hand, seem to be concentrating on electric vehicles. In fact, Japan is eyeing up hydrogen as a source of energy for generating power for homes as well.

The question has to be asked where they’re going to get all this ammonia from. However, it’s possible to take nitrogen gas and water, then zap it with electrical current and turn it into ammonia – and it was an Australian researcher who came up with the tech to do this. It’s kind of like a fuel cell – which breaks down gas to produce electricity – but in reverse: using electricity to produce ammonia. The new Australian technology is considered to be an improvement over the traditional method of producing ammonia (which is needed for making the fertilizer that grows the food you eat), which takes hydrogen gas from fossil fuels and reacts it, spitting out a good deal of CO2 in the process. The new Aussie tech skips the bits involving carbon in any form, as it takes nitrogen from the atmosphere (N2) and water (H2O) and puts out NH3 and O2. O2 is oxygen – what we breathe.

The idea is that in the future, they’ll set up a plant or two in the middle of the outback where there’s lots of solar and wind energy available for generating electricity, pump in some H2O and get ammonia for export AND use in hydrogen cars thanks to the new membrane tech out the other end with zero carbon emissions. It could be asked where they’re going to get the water from in the middle of the Outback but I suppose that it’s not essential to use clean, fresh drinking water for the process, as it’s pretty easy to distil pure water out of wastewater. In fact, one has the very happy vision of a process that takes sewage from cities, whips out the ammonia, urea and methane already in there (bonus!), distils out the water for making more ammonia and exporting the lot; any solids can probably also be used for fertilizer.

It’s going to take a little while for all the systems to get into place. It’s still very early days for HFC vehicles but a start has been made and some of the hurdles have been overcome. A few HFC vehicles have made it onto these shores. The analysts say that it will probably take another decade or so until HFC cars become common on our roads but it’s likely to happen. Look what happened with electric vehicles, after all. Once they were really rare but now there’s charging points just about everywhere you look.

You can find more information here , here and here .

BMW 3 Series Gets Makeover.

BMW‘s evergreen 3 Series has been given a substantial makeover for its impending release. The seventh generation of the car, first released in 1975, will come to Australia for a March 2019, on sale date. There’s a two model range on offer, with the 320d priced from $67,900 plus on roads (includes GST and LCT), and the 330i from $70,900. An xDrive M340i M performance model will hit our shores later in 2019. The 3 Series stays with a 50:50 weight distribution with the additional benefit of a weight loss of up to 55kg. Body rigidity has gone up by 25% to 50% which helps handling, along with the wider front and rear tracks for extra grip. A revamped suspension also comes into play, with a redesigned front end having more camber, and variable damper ratings allowing for 20% stiffer spring rates.

The 3 Series stays with a 50:50 weight distribution with the additional benefit of a weight loss of up to 55kg. Body rigidity has gone up by 25% to 50% which helps handling, along with the wider front and rear tracks for extra grip. A revamped suspension also comes into play, with a redesigned front end having more camber, and variable damper ratings allowing for 20% stiffer spring rates.

BMW’s Adaptive M suspension system is here, with electronically-controlled dampers. This system offers comfort- and sport-focused modes that are changeable in-cockpit. It combines the 10mm lower ride height and geometries of the M sport suspension standard in the 320d. M Sport brakes with blue callipers are standard on the 330i and have four pistons up front, and one piston rears. Handling can be further improved by opting for the M Sport differential with variable torque distribution. An exterior redesign has a one piece grille and the LED adaptive twin headlights up front, a redesigned and sharper look to the iconic Hofmeister kink, and reprofiled taillights with a smoky glaze. The diesel will have a choice of 18 inch diameter alloys, with the petrol fed version having 19s.

An exterior redesign has a one piece grille and the LED adaptive twin headlights up front, a redesigned and sharper look to the iconic Hofmeister kink, and reprofiled taillights with a smoky glaze. The diesel will have a choice of 18 inch diameter alloys, with the petrol fed version having 19s. BMW have bitten the bullet on the options list too. The M Sport Package is standard and the Luxury Line package is an option at zero cost. BMW says the M Sport Package brings the following elements to the 3 Series: BMW Individual High-gloss Shadow Line, with black window frames and air breather surrounds, M Aerodynamics Package with aerodynamic front and rear bumper sections and side sills, BMW Individual interior Headliner in Anthracite, M Leather steering wheel with multifunction buttons, Interior trim finishers in Aluminium Tetragon, 18-inch M light alloy wheels in bicolour, double-spoke design (320d), 19-inch M light alloy wheels in bicolour, double-spoke design (330i), and M Sport Brakes (330i).

BMW have bitten the bullet on the options list too. The M Sport Package is standard and the Luxury Line package is an option at zero cost. BMW says the M Sport Package brings the following elements to the 3 Series: BMW Individual High-gloss Shadow Line, with black window frames and air breather surrounds, M Aerodynamics Package with aerodynamic front and rear bumper sections and side sills, BMW Individual interior Headliner in Anthracite, M Leather steering wheel with multifunction buttons, Interior trim finishers in Aluminium Tetragon, 18-inch M light alloy wheels in bicolour, double-spoke design (320d), 19-inch M light alloy wheels in bicolour, double-spoke design (330i), and M Sport Brakes (330i). Choose the Luxury Line pack and there are: Leather Vernasca upholstery, Interior trim finishers in fine-wood, high-gloss ash grey, Sport leather steering wheel, Instrument panel in sensatec, Sport seat for driver and front passenger, 18-inch light alloy wheels in bicolour, multi-spoke design (320d), and 19-inch BMW Individual light alloy wheels in bicolour, double-spoke design (330i).

Choose the Luxury Line pack and there are: Leather Vernasca upholstery, Interior trim finishers in fine-wood, high-gloss ash grey, Sport leather steering wheel, Instrument panel in sensatec, Sport seat for driver and front passenger, 18-inch light alloy wheels in bicolour, multi-spoke design (320d), and 19-inch BMW Individual light alloy wheels in bicolour, double-spoke design (330i).

Interior space has been increased as well thanks to a 43mm wheelbase increase along with an increase of width of 16mm. Backed against an increased level of trim quality are improved support from the electrically adjustable sports seats, a choice of 3 wood and 2 aluminiom trims, and BMW’s Operating System 7.0. This incorporates a 12.3 inch hi-res display screen for the instrument cluster and a 10.25 inch centre console display screen. New for the 3 Series is Head Up Display, standard on the range. Naturally the safety standards are high with Lane Change and Lane Departure Warnings, amongst others, as standard. Contact Private Fleet to see what we can do for you on price, and contact BMW for more details.

Contact Private Fleet to see what we can do for you on price, and contact BMW for more details.

A Legend Returns: Toyota Supra Is Back.

One of the automotive world’s worst kept secrets was finally let into the public domain today. The Toyota Supra is back in the automotive spotlight and harks back to history with its classic straight six engine up front driving the rear wheels. Dubbed the GR Supra, it’s due to land in Australia in late 2019. The fifth generation platform packs a 250kW/500Nm, twin-scroll turbocharged, six cylinder engine of 3.0L capacity. Power hits the tarmac via Toyota’s eight speed automatic gearbox. Toyota’s Gazoo Racing section has been brought in to work on the cars which are all to be built in Graz, Austria. Testing was held at the Nürburgring Nordschleife and included a session with Toyota’s own president, Akio Toyoda. Launch Control sees a zero to one hundred time of 4.3 seconds.

The fifth generation platform packs a 250kW/500Nm, twin-scroll turbocharged, six cylinder engine of 3.0L capacity. Power hits the tarmac via Toyota’s eight speed automatic gearbox. Toyota’s Gazoo Racing section has been brought in to work on the cars which are all to be built in Graz, Austria. Testing was held at the Nürburgring Nordschleife and included a session with Toyota’s own president, Akio Toyoda. Launch Control sees a zero to one hundred time of 4.3 seconds. The driver can take control of gear changes using paddle shifts on the steering wheel and can select Normal or Sport driving modes to suit their preference and the conditions. The vehicle stability control has a special “track” setting that can be selected, reducing the level of system intervention so the driver has greater control of the vehicle’s dynamic performance.

The driver can take control of gear changes using paddle shifts on the steering wheel and can select Normal or Sport driving modes to suit their preference and the conditions. The vehicle stability control has a special “track” setting that can be selected, reducing the level of system intervention so the driver has greater control of the vehicle’s dynamic performance. Design cues from Toyota’s heritage are evident in the sheetmetal. The S2000‘s long bonnet inside a compact body shape, with the distinctive “double bubble” roof is complemented by the fourth generation’s broad rear flanks and rear spoiler. Toyota’s penchant for pet names is here, with chief designer Nobuo Nakamura giving his team a simple brief around the concept of “Condensed Extreme“, ensuring they were free to express their vision of a pure and individual sports car in a truly original design.

Design cues from Toyota’s heritage are evident in the sheetmetal. The S2000‘s long bonnet inside a compact body shape, with the distinctive “double bubble” roof is complemented by the fourth generation’s broad rear flanks and rear spoiler. Toyota’s penchant for pet names is here, with chief designer Nobuo Nakamura giving his team a simple brief around the concept of “Condensed Extreme“, ensuring they were free to express their vision of a pure and individual sports car in a truly original design.

There are three distinct elements to the GR Supra’s look: a short wheelbase, large wheels and wide stance; a taut, two-seat cabin; and a long bonnet with a compact body that reflects the drivetrain combination of in-line six engine and rear-wheel drive. All are embodied by the “Condensed Extreme” ethos. And although bigger than the two door 86 coupe, it’s a shorter wheelbase and rolls on bigger rubber. The driver and passenger are facing a distinctively designed cabin with a cockpit taking cues from a single seat race car. The seats themselves are race influenced, with thick bolsters for extra side support, holding the driver and passenger snugly. The dashboard is a low slung affair, allowing excellent forward vision, with the asymmetric centre console marking a clear division between the enveloping driver’s cockpit and the more open passenger side of the Toyota GR Supra’s cabin.

The driver and passenger are facing a distinctively designed cabin with a cockpit taking cues from a single seat race car. The seats themselves are race influenced, with thick bolsters for extra side support, holding the driver and passenger snugly. The dashboard is a low slung affair, allowing excellent forward vision, with the asymmetric centre console marking a clear division between the enveloping driver’s cockpit and the more open passenger side of the Toyota GR Supra’s cabin. Toyota’s engineering teams have worked to give the GR Supra a superlative ride and handling package. Structural rigidity is said to be higher than the Lexus LFA supercar, with a centre of gravity lower than the 86 and a 50:50 weight distribution, with the movement of the engine rearwards to achieve that figure, contributing to the end result.

Toyota’s engineering teams have worked to give the GR Supra a superlative ride and handling package. Structural rigidity is said to be higher than the Lexus LFA supercar, with a centre of gravity lower than the 86 and a 50:50 weight distribution, with the movement of the engine rearwards to achieve that figure, contributing to the end result. A newly designed suspension frame has a five-link rear end matched by a double-joint spring MacPherson front. Unsprung weight is helped by using aluminuim for the control arms and swivel bearings. Each corner has 19 inch forged alloys wrapping high-performance stoppers. Every Supra that will be sold in Australia will have an active differential for even better handling.

A newly designed suspension frame has a five-link rear end matched by a double-joint spring MacPherson front. Unsprung weight is helped by using aluminuim for the control arms and swivel bearings. Each corner has 19 inch forged alloys wrapping high-performance stoppers. Every Supra that will be sold in Australia will have an active differential for even better handling.

Pricing for Australia is yet to be confirmed. Contact your Toyota dealer for details of the forthcoming 2020 Toyota GR Supra.

Hydrogen Fuel Cells – The Basic Facts

One of the more exciting vehicles that’s scheduled to come to Australia at some unspecified date in 2019 is the Hyundai Nexo – one of the vehicles recently awarded the Best in Class for all-round safety by Euro NCAP. This vehicle combines regular batteries with hydrogen fuel cell technology. Three vehicles made by major marques have been designed to run on HFCs: the aforementioned Hyundai Nexo, the Toyota Mirai and the Honda Clarity.

Hydrogen fuel cell technology is another option for overcoming our addiction to fossil fuels (the other two are biofuels and electricity). But what is hydrogen fuel cell technology and how does it work? Is it really that sustainable and/or environmentally friendly? Isn’t hydrogen explosive, so will a car running on hydrogen fuel cell technology really be safe?

OK, let’s start with the basics: how does it work?

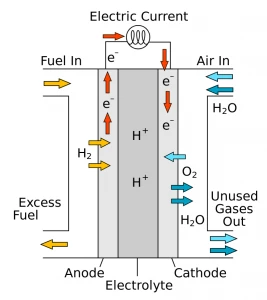

Diagram of a hydrogen fuel cell

A hydrogen fuel cell (let’s call it an HFC for short) is designed to generate electricity, so a vehicle that’s powered by HFC technology is technically an EV. A chemical reaction takes place in the cell and this gets a current going, thanks to the delicate balance between positive and negative ions (all chemistry is, ultimately, to do with electricity). How is this different from a battery? Well, a battery uses what’s stored inside it but an HFC needs a continual supply of fuel. Think of a battery as being like a lake, whereas the HFC is a stream or a river. The other thing that an HFC needs is something for the hydrogen fuel to react with as it passes through the cell itself, which consists of an anode, cathode and an electrolyte solution – and I don’t mean a fancy sports drink. One of the things that hydrogen reacts best with and is readily found in the atmosphere is good old oxygen.

Naturally, there’s always a waste product produced from the reaction that generates the charge. This waste product is dihydrogen monoxide. For those of you who haven’t heard of this, dihydrogen monoxide is a colourless, odourless compound that’s liquid at room temperature. In gas form, dihydrogen monoxide is a well-known and very common greenhouse gas, and it’s quite corrosive to a number of metals (it’s a major component of acid rain). It’s vital to the operation of nuclear-powered submarines and is widely used in industry as a solvent and coolant. Although it has been used as a form of torture, it’s highly addictive to humans and is responsible for hundreds of human deaths globally every year. Prolonged contact with dihydrogen monoxide in solid form causes severe tissue damage. You can find more information about this potentially dangerous substance here*: http://www.dhmo.org/facts.html

For the less alarmist of us, dihydrogen monoxide is, of course, H2O or good old water, like the stuff I’m sipping on right now on a hot summer day. Yes – that’s the main waste product produced by HFCs, which is why these are a bit of a hot topic in the world of environmental motoring.

OK, so air goes in one bit of the HFC, hydrogen gas goes in the other, and water and electrical power come out of it. The next question that one has to ask is where the hydrogen fuel comes from (this question always needs to be asked: what’s the source of the fossil fuel substitute?). The cheapest source of hydrogen gas as used on HFCs is natural gas, which is, unfortunately, a fossil fuel. So are some of the other sources of hydrogen gas. However, you can get it out of methane, which is the simplest type of hydrocarbon. Methane can be produced naturally by bacteria that live in the guts of certain animals, especially cows. Not sure how you can catch the methane from burping and farting cows for use in making hydrogen gas for HFCs. And, just in case you’re wondering, some humans (not all!) do produce methane when they fart. It’s down to the particular breed of bacteria in the gut (archaea if you want to be picky – they’re known as methanogens). They’re as common as muck – literally. So yes, there’s potential for hydrogen gas to be produced from natural sources – including from sewage. The other thing is that producing hydrogen gas from methane leaves carbon dioxide behind. But this has way less effect as a greenhouse gas than methane, so that’s a plus.

If you’re currently feeling that HFCs might not be quite as environmentally friendly after all and we all ought to drive straight EVs, then I encourage you to do a thorough investigation of how the electricity used to charge EVs comes from. It’s not always that carbon-neutral either. Heck, even a bicycle isn’t carbon-neutral because when you puff and pant more to push those pedals, you are breathing out more carbon dioxide than normal. All in all, HFCs are pretty darn good. The worst thing they chuck out as exhaust is water, and the hydrogen gas needed to power them can come from sustainable sources – very sustainable if you get it from animal manure and/or sewage, which also means that poop becomes a resource instead of a problem to get rid of. They’re doing this in Japan – and they’ve also managed to get the carbon bits of the methane to become calcium carbonate, which sequesters carbon and has all sorts of fun uses from a dietary supplement through to agricultural lime.

Another plus about HFCs is that they are a lot more efficient than combustion engines. A large chunk of the potential energy going in turns into the electrical energy that you want, which is then turned into kinetic (motion) energy by the motor so your car gets moving (or it turns into some other form, such as light energy for the headlights or sound energy for the stereo system). Some comes out in the form of heat. Combustion engines waste a lot of the potential energy in the form of heat (lots of it!) and noise (ditto).

The amount of electrical energy produced by a single HFC isn’t going to be very large, so inside any vehicle powered by hydrogen technology, there will be a stack of HFCs, which work together to produce the full amount of oomph you need. The fun part in designing a vehicle that runs on HFC technology involves ensuring that the stack has the oomph needed without being too heavy and working out where to put the tanks of hydrogen gas. However, this isn’t too hard.

The other problem with manufacturing HFC vehicles is that the catalyst inside the cells is expensive – platinum is common. This is probably one of the biggest barriers to the spread of the technology, along with the usual issue of nobody buying HFC vehicles because nobody’s got an easy place to get the gas from and nobody’s selling the gas because nobody’s buying HFC cars. They had the same issue with plug-in EVs too, remember, and we all know how that’s changed. However, last year, our very own CSIRO came up with some technology to get hydrogen fuel for HFC vehicles out of ammonia and they want to go crazy with this and use it all over the show. This is exciting stuff and probably deserves a post of its very own, so I’ll tell you more about that another day.

I feel in the need for some 1,3,7-trimethylxanthine theine combined with dihydrogen monoxide in solution with β-D-galactopyranosyl-(1→4)-D-glucose and calcium phosphate, also known as a cup of coffee, so it’s time for me to stop and to wish you safe and happy driving – hopefully without too much methane inside the cabin of your car on long journeys!

*Some people in the world have far, far too much time on their hands.