Fueling your Car

Paying For The Roads We Drive On

Across the Tasman, there are plenty of people getting annoyed at the increase in large, damaging potholes that have developed over the last few years on NZ’s tarmac road surfaces, even on main State Highways. Over there, for quite some time, EV owners have been getting a free ride on the coattails of motorists using an internal combustion engine (ICE) vehicle and who pay their fair share of road user chargers (RUCs) and/or a large portion of tax levied on the fuel at the pumps for the roading upkeep. This got me thinking about how should we be fairly introducing EVs to the masses while maintaining our roading systems? I realize it’s likely to be a bit contentious, but it’s not a question just for New Zealand’s new government to answer; it is also worth giving a bit time to thought and discussion here in Australia.

In Australia, we pay quite a lot of money into the pool of government funds that is received on yearly vehicle registrations. According to the Australian general insurance provider, GIO, the average cost for a family car is likely to be around $1240 per year. The excise tax (an indirect tax charged by government on the sale of a particular good or service) on the common fuels used in Australia (as of 1 February 2022) is $0.442 per litre. Introducing a direct road user charge as a replacement for fuel excise tax is something that has been bandied about at various high levels of government in Australia. The idea gains extra weight particularly when you consider the seemingly imminent transition from fossil-fuel and the ICE to electric vehicles (EVs).

A transition from ICE vehicles to EVs changes the maths and raises eyebrows for those harbouring the more philosophical questions involving fairness and equality for all socioeconomic groups. Without some form of direct user charge for the EV motorist, they would otherwise make no contribution to the roads’ upkeep.

If, in the future, we do end up going entirely electric, the current $12 billion or so of annual revenue from fuel tax will need to be replaced from some other scheme or source. It seems quite economically sound to simply charge for owning and using cars on a scale according to the number of kilometres driven.

Adding another aspect to your discussion on this topic down at the pub might earn you a free drink, so how about considering the damage caused to roads according to the weight of the vehicle driving over it? A UK report carried out by researchers at the University of Leeds suggested that EVs can damage roads at twice the rate of an equivalent-sized ICE vehicle. According to the data, the average EV adds 2.24 times more wear and tear to roads than an ICE vehicle of similar size. They also think that battery electric vehicles (BEVs) with a mass of over 2000 kg contribute 2.32 times the rate of road deterioration.

So could the fuel excise could be scrapped altogether, and all vehicles should be taxed via a user pays system based on the weight/mass of a vehicle? This sort of deal might actually help lower emissions in the long run because the lighter the car, the more frugal it is, EVs, hybrids, and ICEs all included. The cost of road repairs is also related to the CO2 emissions as well, so the fewer road repairs are required, the lower the emissions emitted – well, in theory anyway. What do you reckon?

Hydrogen-Based ICE?

How does a 2.0-litre 4-cylinder engine boasting 302 kW of power at 6500 rpm and 500 Nm of torque between 3000 and 4000 rpm sound to you? To my ears, this is pretty impressive stuff on any given day.

Big entities AVL Racetech and Hungarian HUMDA Lab have used their know-how to work on advancing the hydrogen internal combustion engine (H2 ICE). These engines have long been known for their low performance and lean-burning capacity, but AVL Racetech and Hungarian HUMDA Lab have succeeded in producing something that changes this impression completely.

According to Toyota, the future of vehicle transport and mobility lies in this new type of engine and its resulting powertrains. The 2.0-litre H2 ICE was put through its paces on a testbed and confirmed that the following top values calculated previously in simulations were a reality. Apart from the benefits that the H2 ICE has for the planet in reducing fuel emissions, the level of power that this new technology can produce is staggering.

To put some context on the level of power that this 2.0-litre H2 ICE motor produces, let’s think of it this way. The brand new engine can reach highs of around 153 kW (205 horsepower) per litre, which is even more than the Bugatti Chiron’s 185 horses per litre!

Cleverly designed PFI water injection systems moderate the combustion in the chambers and prevent any potential engine damage from occurring. The PFI water injection system introduces water into the intake air, which improves pressure levels. It also reduces the temperature of the combustion chamber as it evaporates. The air demand, which is lower than during lean combustion, is provided by a waste gate turbocharger that has been especially designed for the sole purpose of improving pressure levels and reducing the combustion chamber’s temperatures.

The H2 ICE process differs from hydrogen combustion in a fuel-cell vehicle, which works more along the lines of a traditional engine but using hydrogen instead of gasoline. So, the H2 ICE converts hydrogen into electrical energy to power an electric motor.

The H2 ICE project leader, Paul Kapus, Manager of Development Spark Ignited Engines, stated that. “At the end of 2022, we announced for the first time, that we would be working on a two-litre, hydrogen-powered racing engine with stoichiometric combustion and PFI water injection… Our goals were 500 Nm of torque and an output of up to 300 kW… We are proud to have been able to validate those figures on the testbed.”

Ellen Lohr, the director of Motorsport AVL, mentioned that the results of the testing of the new motor means that it is a competitive racing package with this technology. The goal for the AVL Racetech team is to lead motorsport into a sustainable future. The next step will be to test the new H2 ICE concept in the heat of battle on a racetrack.

This technology could surely influence the direction of EVs into the future. Watch this space!

EV Etiquette

I recently came across a news article about another publicity-related EV road trip in the USA, this time involving the US Energy Secretary. I won’t go into the full details of the road trip in this article (you can read it here ) but it seems as though Ms Granholm was guilty of some very, very bad manners. Specifically, the people in this road trip convoy encountered the same problem as the CEO of Ford USA in his Route 66 road trip, namely that there was a bit of a shortage of EV charging points. You may be scratching your head at this point, as you’ve probably seen a few of these stations cropping up all over the show – they seem to be in the carparks of every second big box store. However, you have to remember that although there seem like there are plenty of them and they’re easy to find, charging up takes a lot longer than filling up. If you come along to a petrol station and you find that all the bowsers are taken, you won’t have to wait more than a few minutes until one comes free and its your turn. However, in the case of an EV charging station, you’ll have to wait for the other person to finish charging (which could be more than half an hour) and then you’ve still got to charge your own vehicle. This can put a serious dent in your working day if you hadn’t planned for that extra time.

The very rude solution found by Granholm et al. was to send an ICE vehicle ahead of the convoy to park in the EV charging space to reserve it, and they got away with this, as that particular state didn’t have a law against ICE vehicles parking in EV charging spots. However, it put quite a few backs up, especially for one family that came along with a grumpy baby in their EV really, really needing to juice up so they could run the air conditioning. Not a good look at all.

Of course, this highlights a problem with the infrastructure that it’s beyond you or me to solve. If governments are serious about encouraging the uptake of EVs, then they’re going to need to do something about charging stations (and capacity for electricity generation, but that’s another story). Nevertheless, given that EVs are probably here to stay, what can you do to ensure that you don’t become one of those drivers who gives EVs a bad name? Here’s a list of my top tips:

- Factor in the possibility of other people using the charger when you plan your trip and calculate the time needed. You may not be able to guarantee a spot at the DC fast charger.

- If someone gets to the charger before you do, don’t throw a hissy fit. They’ve got as much right to it as you do. Definitely don’t do anything pushy, like sending someone ahead to stand (or park) in the spot you want, or start a fight (yes, this has actually happened).

- Think of public charging points as emergency top-ups. It’s not like the situation with ICE vehicles where you can only fill up at the garage. So charge at home (and at work) as much as you can. If you don’t have to use the public charger, don’t.

- If you have to go slowly because you’re running out of charge and the nearest charging station is still a few kilometres down the road (what my ICE-driving brothers refer to as the Nissan Leaf Limp), don’t hold up traffic behind you. Pull over to the side and let them pass.

- Never unplug someone else’s vehicle from the charger while its charging, even if that car is unattended. Some apps may allow you to unplug a fully charged car, but if you don’t know for certain, then don’t do it.

- Don’t just park in the charging point, even if you are driving an EV. They are charging points, not EV-only car parks.

- Some charging points have time limits. Respect these.

- If you’ve left your car to charge while you do a spot of shopping, keep an eye on progress via the appropriate app on your phone.

- Above all, remember that although you have an EV and you’re doing it to save the planet, this does not give you the right to be a jerk to people who drive ICEs (and they don’t have the right to be jerks to you, either). Be proud of your choice, sure, but don’t look down on other people – they might not be able to afford an EV, or an EV might not suit their workplace, or they might be country bumpkins for whom EVs don’t really work. So be a good EV ambassador.

The Stanley Steamer

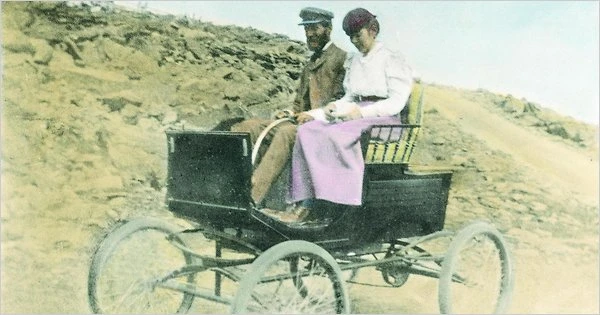

Now that electric cars are becoming more popular, and there’s talk about hydrogen fuel cell vehicles, our attention has been turned to what’s powering our cars. In this context, it’s interesting to one of the solutions used in the past as an alternative to petrol or diesel power: steam.

A good friend of mine, during a discussion on fuels, EVs and similar topics, wondered whether steam could be used to drive a car. I was sceptical, but it turns out that I was wrong. A little over 100 years ago, steam-powered cars were indeed a thing. They aren’t just a steampunk fantasy, as I had thought.

One of the most popular type of steam-powered cars was invented by the Stanley twins in the USA at the end of the 19th century. Bizarrely, F.E. and F.O. Stanley also invented one of the first photographic airbrushes, as they started their business ventures in the area of photography. However, automobiles were a lot more interesting, and they started the Stanley Motor Company in 1902 after an earlier attempt with a company known as Locomobile.

At that time, many internal combustion engines that ran on petrol or diesel needed a crank to start them up. These cranks were tough to turn and required a fair bit of elbow grease. They could even be dangerous, as if the car backfired while someone was cranking it, this could leave the person doing the cranking with a broken arm. However, the Stanley Steamers used gasoline (petrol) to generate a good head of steam, which provided the power to turn the wheels, and they didn’t need cranking. Stanley Steamers were designed with safety in mind, as they had a system in place to prevent the boiler from exploding if too much heat and pressure was generated.

For its time, the Stanley Steamer had some fairly impressive specs. It was a rear wheel drive affair, and didn’t require a transmission or clutch system, meaning that they were easier to drive. The power output varied depending on the engine type. The basic model (the compact engine) could deliver 7.5 kW. Two twin-cylinder engines were developed, the smaller one (3¼-inch bore and 4¼-inch stroke) also put out 7.5 kW, but the larger one (4-inch bore and 5-inch stroke) delivered a massive 15 kW.

For its time, the Stanley Steamer was quite fast. In fact, a customised version of the Stanley Steamer known as the Stanley Rocket Racer became the holder of the world land speed record for automobiles over a mile, clocking up 204 km/h in a trial at Daytona. This record stood for five years, and remained the best time over a mile for a steam-powered car until 2009.

As time went by, the Stanley twins refined their design, switching to lightweight aluminium bodywork and features such as condensers that harvested the steam so that the range of the water tank could be extended.

However, the makers of cars with internal combustion engines managed to find an alternative to the crank: the electric starter motor. This meant that the drawbacks of cranks were no longer, and the Stanley Steamer lost its biggest attraction, especially with the rise of cars produced via mass production and sold cheaply, Ford being the best known example of these. The Model T cost less than a quarter of the price of the Stanley Steamer and the engine of even the base model, which ran on petrol, kerosene or ethanol (now, that’s an idea worth revisiting), had the same power output as the best of the “Flying Teapots”, as the Steamers were known.

Given the stiff competition from the internal combustion engines inside the Model T and similar vehicles, things didn’t look good for the Stanley Steamer. Eventually, after one of the twins died (in a car crash, of all things), the company went under, ultimately closing in 1924.

The Stanley Steamer wasn’t the only steam-powered car in existence. Others have been made and sold, especially the Doble, and the idea has come back now and again over the past century or so, especially given concerns over pollution and the availability of fuel. Saab had a go at making a steam car in the 1970s during the fuel crisis of that decade (the project failed, unfortunately). An Australian inventor and enthusiast named Ted Pritchard tried to develop one in the 1960s and beyond and had some success. Until he died in the early 2000s, he was pushing for the use of steam-powered cars.

External combustion engines (which is what a steam engine is) aren’t as efficient as ICEs but they produce a lot less pollution, as they don’t burn as much fuel. They are heavy, thanks to the need for a strong boiler and a water tank. They can accelerate quickly once they’ve got a good head of steam up, but they do need a fair bit of time to boil and let the pressure build; this is one of the things that experimenters wanting to bring back the steam car try to work on.

And what about the future? Given the push towards vehicles that are less dependent on petrol and diesel, will we see attempts to make the steam car come back again? Electric cars have made a comeback (and how!), so perhaps steam will do the same.